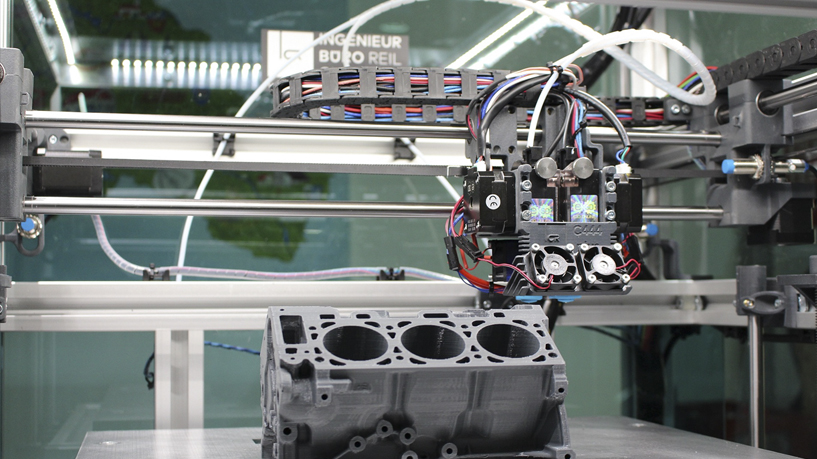

During its initial days, 3D Printing was perceived as a marvel accessible to a limited cohort. Times have changed and so have the accessibility and perception on 3D printing technology. Cumbersome tasks like modeling and structural analysis can be done more easily with this emerging technology. The industries are undergoing major changes with the new technologies and customization features entering the marketplace. Here we have a look at a few sectors that have already started adapting to the change of the tide and in improving efficiency by employing 3D in its production processes.

3D printing technology has employed applications in the design stages of construction projects. Architects can now print models of buildings for visual aid and design analysis. Low cost temporary buildings are being 3D printed ready to live-in. Furthermore, machine construction of infrastructure projects could eliminate the risks of human error.

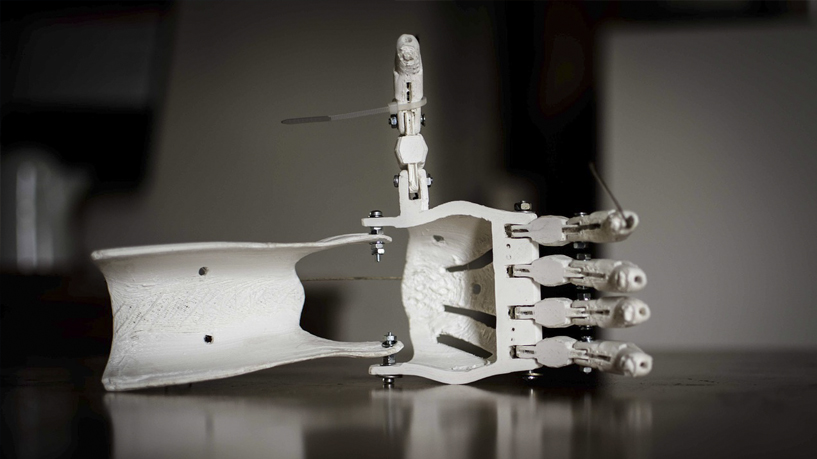

Prosthetics are expensive and are not currently the most readily available solution for a common physically challenged person.Besides it may take months to receive an order. For people who use prosthetics, the quality and comfort of the device determines the range of their daily activities; so customization is paramount. 3D printing technology is well suited to meet that need. It also drastically cuts costs and production time ; a 3D printed prosthetic can typically be made in a single day.

Source: Pixabay

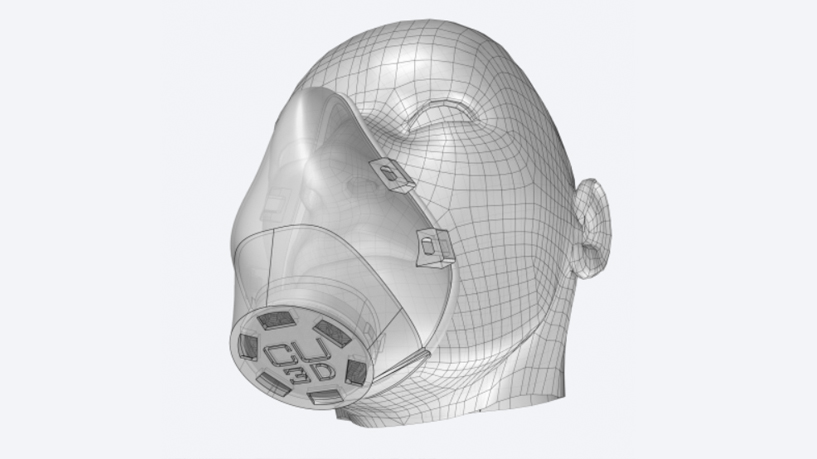

In the fight against COVID, 3D Printing enabled volunteers to 3d print the crucial parts such as ventilator valves, N95 Masks.

Scientists all over the world are researching to develop face masks using 3D printing technology. In general, cloth masks or medical-grade ones are less efficient for doctors who are working in treatment centres. The idea behind producing 3D printed masks is to ensure that there is less exposure to viruses while breathing and can be reused after serialization. Few manufacturers have published an open-source STL digital file of N95 mask for COVID19 application. This will inspire others to make respirators quickly and facilitate the doctors. Medical grade 3D printing materials are available in the market and are being constantly researched. One of the materials called Copper3D claims to have good antimicrobial and antiviral properties. This mask had a modular fine particle filtration system that was tested further. The manufacturers have to prepare the slicing model of the mask in software with 3D print settings of infill percentage in the range of 20 – 30 % without support and rafts. The orientation of the model was also tested and concluded for effective print time and less material wastage. The mask is still under testing and medical approvals.

Source: Copper3D

The fact that materials like titanium and aluminum can be 3D printed, paves way for the aviation industry to enter the world of 3D printing. 3D printing cut the cost and production time in building of airplanes. This is much needed as The International Air Transport Association (IATA) predicts that 7.2B passengers will travel by air in 2035.

Source: Pixabay

3D printing can produce strong, lightweight equipment, and with companies racing to explore space, rapid prototyping is key. Several companies have been looking into how they can harness 3D printing. NASA has released open source models of printable projects, such as the Apollo 11 landing site. NASA even held a competition where designers could 3D print a habitat usable on the moon or mars, in which AI SpaceFactory bagged a whopping prize of $500,000.

The race for smaller and sleeker phones is already underway. 3D printing could be the next big boost in bridging the gap to building smaller and customizable electronics. Manufacturers can use 3D printing to create devices as a unit . This is possible because printers can combine conductive ink with the metals and plastics that make up a product’s external feature. 3D printing also offers greater freedom in design as it can eliminate the need for flat circuit boards, allowing for devices of all different shapes and sizes.

Designing furniture has traditionally required significant time and investment. 3D printing simplifies the process, allowing designers to test concepts more quickly and offer customers lower prices. A custom table that would typically cost thousands of dollars could cost just a couple hundred when printed. The fact that the density of the printed material can be changed, helps in making the furniture lightweight as suited to the specific need.

Farm equipment is made up of several small parts. If a piece breaks during a harvest, the time it takes to get a replacement delivered can be problematic. 3D printing presents an opportunity to be more self-sufficient, especially for smaller farms. It’s possible to imagine future scenarios where rural farmers are able to print any spare part they may need, eliminating costly trips to the supply store. They could experiment with printing materials beyond metal, like recycled plastic, and develop a circular economy.

Imagine your meal being prepared on the table, while you relax on the sofa might sound like magic but it is not far from being a reality. The main value of 3D food printing lies in convenience and customization. As specialized diets become more common, 3D-printed food is poised to enable more personalized on-demand eating experiences. Originally limited to sugary, processed confections, the technology has made strides to encompass a much wider range of options

Fast fashion is disrupting the fashion industry, and now it gets accelerated with 3D printing technology. How good it would be if you can print your dress or your make up in a 3D printer? Recently the world’s first make up 3D printer was introduced by Mink. As an early adoption, 3D printers are used to print accessories such as jewels, wearables etc. 3D printed dresses are not available right now, and it will not take long for the companies to surprise the consumers with customisable 3D Printed clothes.

Source: Mink

This is just the tip of the iceberg with a technology offering such wide applications, like 3D printing. The possibilities are endless and the only limit is that of your imagination.

Amrita TBI Fab Lab facilitates the innovators to iterate their Ideas with help of digital fabrication facilities.

To Know more about 3D printing and Training at Amrita TBI Fab Lab click here